At “Tools of the Trades” I picked up another “Buck Rogers” era tool from Millers Falls – the No.104 hand-drill. The 104, in addition to the No.308 were introduced in the late 1940s. The 104 is the smaller of the two drills, with a maximum jaw size of 1/4″, versus 3/8″ for the 308. Interestingly, prior to the introduction of this version of the 104, there was another No.104, with the standard iron frame, hardwood head and a crank handle with a wierd urn-shaped body cap. An evolution of sorts then, iron to aluminum, hardwood to plastic. The new drill was designed by Francesco Collura – he also designed the Millers Falls “Buck Rogers” hacksaw.

The design patent for the drill (No. 140,811), “ornamental design for a hand drill”, was issued in 1945. A single-speed hand drill, it was somewhat unique in having an enclosed gear mechanism, effectively keeping out sawdust and dirt. The frame and gear cover are made of die-cast aluminum, making the drill incredibly light. According to the catalog entry (shown below), “the steel spindle runs in an ‘Oilite’ bushing”. Oilite is a porous bronze or iron alloy (introduced in 1930) impregnated with an oil lubricant. The first photograph below shows the pristine condition of the gear inside the cover, the second photo shows the gear casing on the frame. The mechanism is maintained by putting oil in the hole used to hold down the gear cover.

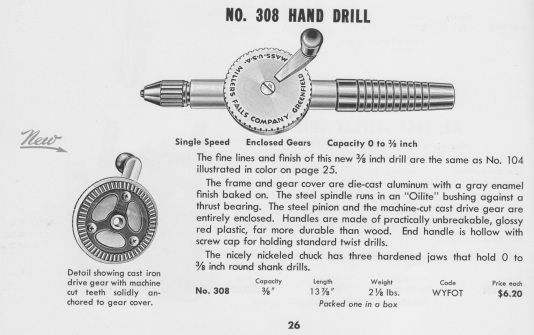

The handles are “unbreakable” red plastic (likely Tenite), the frame and gear cover are gray baked enamel, the chuck nickel plated. The enamel coating, is the one part of the drill that often suffers from wear, becoming pitted. The nickel plating on the chuck often flakes off. Here’s the entry from Millers Falls Catalog #49.

The drills were sold with eight fluted drill points, however more often than not these disappear over the years. I tried the drill with a 15/64″ bit drilling into oak, and it just doesn’t have the power of a Millers Falls 2A, probably due to the lack of leverage due to the short handle, and a single pinion. The No. 104 is fine for drilling small holes, but anything beyond 1/8″ can be challenging.

Below is the catalog entry for the No.308, showing the detail of the cast iron drive gear.

This may be a candidate for restoration (I bought it for $12) – if I can deal with the gray paint on the body, and the flaked chrome plating on the chuck.