Month: March 2017

A Swiss chair

A stool from Werdenberg Castle in Switzerland, showing the use of textured punches.

Nearly time for … Tools of the Trades

Get ready for it… its coming soon. Tools of the Trades. Sunday, April 2, 2017. 10am-3pm. Best tool show in Canada – drop by to pick up some freshly picked tools.

Block plane depth-adjustment mechanisms (iii) – the lever

Likely depth-adjustment mechanisms first evolved into into the use of levers. These levers were of one of two types: static and moveable (allowing for lateral adjustment of the blade). The lever mechanism usually has some form of teeth which engage in the back of groves cut into the blade. This form of depth adjustment mechanism generally relies on three forms of lever cap to lock down the blade once the optimal position is found: (i) a disc-type screw clamping mechanism; (ii) a cam-type clamping mechanism or (iii) a butterfly-style clamping mechanism.

The first form of lever is a one often seen in early Stanley planes, with the lever encased inside a cage: pulling the lever up causes the blade to retract, pushing the lever down causes the lever to insert.

A Stanley No.103, and Stanley No.120

These mechanisms relied on fine groves on the back of the blade meshing with corresponding grooves on the saddle of the “cage”. The lever “cage” is held in place at the pivoting point by a ball-and-socket type joint, and at the rear by a pin which anchors it to the planes sole. These mechanisms are very jittery, and only offer a small range of movement, typically 1/8″. Because the cages saddle is curved to allow for movement, there is also limited contact point between it and the grooves in the blade.

The “cage”, and pivoting lever, and fine groves on the blade.

The next form of lever-based mechanism, uses a pivot attached to an integral saddle. These levers often suffer from overhanging the end of the plane, thereby decreasing their usability as it is easy to accidentally knock the lever and put the blade out of sync.

A Birmingham, and Ohio Tools No.09½

The levers on these pivot mechanisms, often have 2-3 large teeth which engage with the back of the blade. The blade either has deep grooves, as found in the Birmingham.or a rack-and-pinion like mechanism, as found in the Ohio No.103.

Rack and pinion mechanism of the Ohio No.0103

The final, and very unique depth-adjustment mechanism is that of the Hobbies No. 8. It uses two pivotal levers to control both depth adjustment and lateral positioning of the blade. As the top lever is moved right, the blade inserts, when moved back to the neutral centre position, it retracts. The lower lever is used to make minor lateral adjustments.

A closer look, shows a blade with holes in the blade that meshes with a pin on the adjustment mechanism. This mechanism works quite well, as once the wing-nut locks the laver cap down, it is very difficult to accidentally move the levers. The entire lever mechanism sits on a “rearwardly and upwardly inclinded bracket“.

This lever-based depth adjustment mechanism is one of the few which has a patent. It’s British patent (No.208,401) was received in 1923, so it was a late development, when most block planes had moved to alternate mechanisms. The objective of the patent was to provide an “improved and simplified means for effecting the adjustment of the plane iron”.

Trees in winter

Trees in winter

A copse of trees,

blanketed in snow,

long branches bare..

Against the cold of winter,

the mighty trees stand,

sleeping,

despite the snow.

Block plane depth-adjustment mechanisms (ii) – early forms

The earliest depth adjustment mechanisms were manual, i.e. just like wooden planes the depth adjustment mechanism involved manually lowering or raising the blade and then tightening the lever cap. Adjusting the depth of the blade in these block planes may involve using a plane hammer, in a similar way to how wooden plane blades are adjusted. The difference between wooden and metal block planes is that the metal ones usually employ a lever cap with some form of clamp screw. These clamp screws were historically very rudimentary, but as time progressed, they graduated to a more refined, machined form. Below is a Sargent No.107 from their 1894 catalog. This is an extremely rudimentary plane, and is an indication of the lower cost of the plane ($0.60 versus the No.1307 which had depth, and lateral blade adjustment, and throat adjustment mechanisms, and sold for $1.75).

This simple form of blade adjustment, i.e. none, remained important in lower cost planes, and planes that were too small to accommodate a depth adjustment mechanism. Below are two examples of manual blade depth adjustment. On the left is the Hobbies No.10, with the blade resting on the butte attached to the plane body. On the right is a Pexto with similar set-up. The Hobbies clamps the blade down using a butterfly nut attached to the lever set screw. The Pexto uses a more traditional clamp screw.

Below are two examples showing the diversity in circular clamp screws. On the left is a simple clamping screw from a UTIL aluminum block plane, with very large lugs on the side of the wheel. On the right is a more refined Record No.102 with a wheel that has fine linear knurling. The smaller clamp screw has the added advantage of sitting under the lever cap, and is less prone to accidental movement when being used.

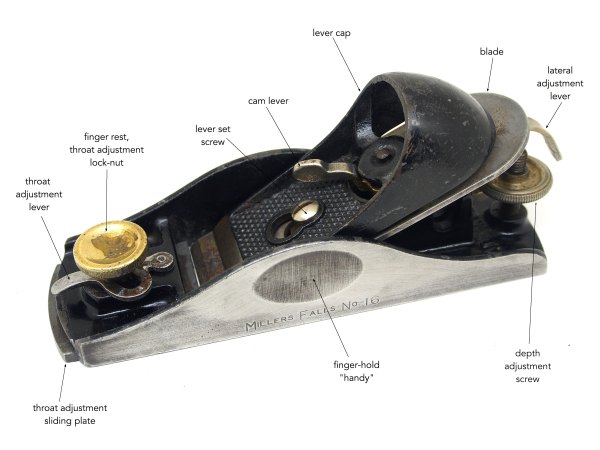

View of a block plane

Anatomy of a block plane

In its simplest form, a block plane has a body, blade, and some form of lever cap to hold the blade in the plane. There are many different renditions of block planes, mostly due to different forms of mechanisms for lateral/depth adjustment, the addition of a mouth adjustment mechanism, or the cost of the plane. Anatomically, less expensive block planes have few adjustment mechanisms, and often the simplest means of holding the blade in place – the fewer the parts, the less costs are involved in the manufacturing process. Yet most block planes can be distilled down to a few basic features.

These pictures show the major parts of a block plane in the context of a Millers Falls No.16.

There is extensive variability amongst differing designs over the past 150 years, however the core ideas remain the same. In general block planes have up to three core adjustment mechanisms, and one clamping mechanisms. Adjustment mechanisms found on block planes include:

- throat adjustment: a mechanism used to adjust a sliding plate at the toe of the plane to increase the size of the block planes throat, and hence the fineness of the cut.

- depth adjustment: a mechanism that allows the depth of the cut to be adjusted.

- lateral adjustment: a mechanism which allows the blade to be adjusted from side-to-side in order to ensure the cutting edge is perpendicular to the length of the plane.