Years ago I bought a corded drill, manufactured by Black and Decker in Brockville, Canada. It is the ubiquitous Black & Decker U-3, ¼” utility drill, an atomic-era electric drill which appeared in the mid 1950s. It sported some innovations for the home user – a three-pronged plug with an “industrial-type” ground wire, and a geared chuck, which although was being used in industry hadn’t yet been widely adopted on residential power tools.

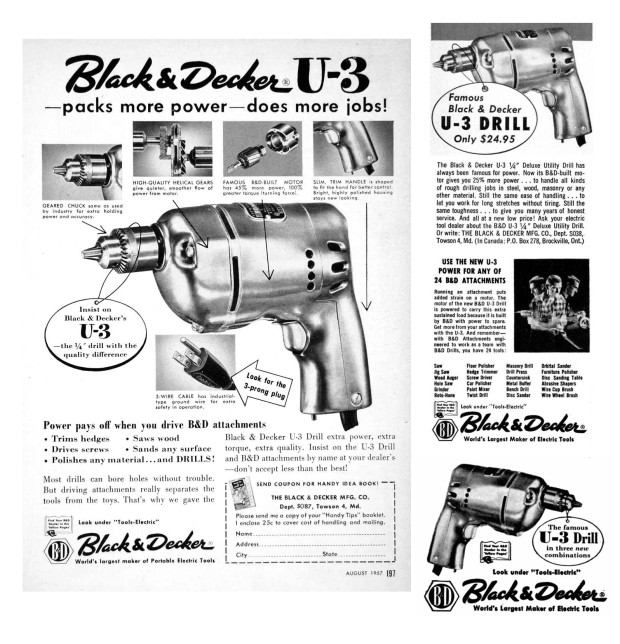

Ads describing the powerful U-3 drill!

These 1950s era tools were often constructed of aluminum. This could have been in part because of the ease in casting it into various shapes, and its extensive use during WW2. The increasing use of plastics in the late 1950s would eventually see the number of aluminum components diminish. The 1950s was an excess of aluminum, as it found its way into every aspect of people lives – toys, cookware, cameras, tools, flashlights, etc. Why did aluminum reign? Tools made of aluminum have a gleaming, almost delicate beauty. Aluminum is also strong, and highly resistant to corrosion.

It was one of those drills that could power a multitude of different add-ons, from a jigsaw, to an orbital sander or paint mixer. These tools were extremely common up until the 1980s, made especially for the home handyman who didn’t need separate tools. The early tools were likely quite well built, but by the 1970s the mix-and-match add-on tools being manufactured had become cheap (we had a set at home). The drills had gone from being constructed of metal to mostly plastic.

Some of the available attachments.

The beauty of this drill is one thing, the ergonomics are a completely different story. As you can see in the photograph below, the handle is quite short which means it is challenging to grip. It was advertised as having a “slim, trim handle”, which I think was more marketing spin than anything else. More short and stubby! The other downside to the all-metal construction is that it is heavy.

Too hard too handle?