A cool mosaic wood tile wall at Lululemon Athletica store at a Yorkdale Mall.

Month: July 2017

Sandpaper for the Festool RO125 sander

For sandpaper there are two choices, the Festool paper, of which there are numerous types, and Abranet abrasive. Now the Festool abrasives are not exactly cheap, and it’s impossible to buy less than 10 in a packet… and there don’t seem to be any “test packets”, full of a range of abrasives (well except for the “125mm Sanding Disc Set” with 150 assorted discs) . For the cost of the sander, they could almost include this, instead of the lonesome 80-grit sanding pad. The Abranet is aluminum oxide bonded to a tough polyamide mesh. From the cost perspective, the Abranet averages about C$1.45 a disc, whereas the Festool Rubin2, Granat and Brilliant 2 range between C$1.80 and C$2.00 (Lee Valley pricing for a pack of 10). Pricing reduces significantly when buying in bulk packs. For example the Granat abrasive is C$2.00 each when bought in a pack of 10, C$1.00 in a pack of 50, and C$0.80 in a pack of 100.

Rubin, 60-grit

Festool offers a multitude of abrasives.

- Rubin 2 -(close-coated aluminum oxide) this is the primary one for raw wood. P40-P220

- Granat – (hardened aluminum oxide abrasive with ceramic grit and stearate coating ) used for solid surfaces, plastics, composites. P40-P1500.

- Brilliant 2 – For use with paints and varnishes. P40-P400. P40 to P60 for rapid removal, stripping stubborn paints and finishes.

- Saphir – (aluminum oxide) For sanding thick coats on hard surfaces, P24-P80. Suitable for sanding wood, paint, plastics, fiberglass, composites, concrete and steel.

- Titan 2 – (aluminum oxide) Suitable for solid surface and automotive finishes.P80-P3000

- Platin 2 – (silicone carbide) Suitable or finishing fillers, finish coats, solid surface, fiberglass and plastics. S400-S4000

- Vlies – (aluminum oxide fibre-mat) Suitable for cleaning, scouring and scuff sanding a wide range of materials. A100-A280

I would suggest Rubin 2 for rough sanding, followed by Brilliant 2 for higher end 320/400 grit sanding. I have used Rubin 2, 120 grit, followed by 180 grit, followed by Granat 220 grit for finishing hard maple to obtain an uber smooth surface. I have also used a Granat 320 to finish sand drywall, and it does an exceptional job.

Everything decays… mostly

The photo below is from a boat sitting on blocks in the harbour in Reykjavik. What it represents is a metaphor for most things on the planet – there is very little humans make that does not eventually deteriorate (well most things – glass doesn’t decay, but wears away once broken, and plastic, well some say a plastic bottle may take 500 years to break down). Marine environments may be the worse, but the biggest culprit is water. Wood will eventually rot away, and metal rusts. For wood to rot of course you need the presence of warmth, oxygen, and moisture. Take one of these away, and the process slows immeasurably. Same for metals really. That’s why logs underwater, and even wrecks in cold climes for 100+ years survive – no oxygen.

Check out this post which describes centuries worth of shipwrecks in the Black Sea. Below 150m, there is next to no oxygen, so the wood on some of the wrecks was so well preserved there were visible chisel and tool marks. On some wrecks, even coils of ropes were preserved. It’s also why underwater logging has become such an industry, reclaiming logs that sunk during logging 100+ years ago. Above water though, its another matter altogether. That’s the problem with oxygen… it plays together with moisture and warmth to rot things. Wood decays, because the moisture and temperature conditions allow fungi to grow in the wood tissue.

Ironically the woods that are most resistant to decay are also those which are hardest to work with. Black locust is a good example, or tropical woods such as ipe, or lignum vitae. Ipe can be cut (but not by hand), but challenging to glue, and impossible to shape. Old growth redwood was exceptional for decay resistance because it came from large trees with a good portion of heartwood. Newer growth trees have larger bands of sap wood, which offers less resistance. That’s why newer wood shingles won’t last as long, despite coming from the same species.

What we need is a fast-growing, CO2 absorbing, workable, highly rot-resistent wood. Think, the workability of beech/birch, the growth speed of the hybrid poplar, the rot resistance/strength of ipe, and the CO2 absorption ability of the silver maple (like who knew).

Reclaiming wood

Do we do enough to recycle wood from old houses, or is it easier to just dump it in a landfill? I see a lot of houses in my neighbourhood that are renovated, and the true 2″×4″ pieces of lumber are thrown into a dumpster. Kudos to those companies that reclaim the wood from larger buildings, but we ultimately need to do a better job reclaiming the wood from smaller buildings, and municipalities need to do a better job requiring construction waste to be sorted properly.

A cautionary tale

My wife bought me this trivet a couple of Christmas’s ago (from Stinson Studios), made from a section of tree (which I believe is Red Cedar?). It has sat in a sideboard in the dining room where the climate is fairly much the same all year round. Yet yesterday when I pulled it out of the sideboard, I noticed a large crack – coming from one of weak points along the trunk.

This is a cautionary tale in the realization that wood is an organic object. It moves, even in its life after life as a tree. The reality is round cuts made this way nearly always split. Boards made of quarter-sawn lumber don’t usually have these problems, but wood cut in this cross-cut fashion cracks because of the increased shrinkage in the rings, something called tangential shrinkage (wood shrinkage in a direction tangent to the growth rings), versus radial shrinkage (wood shrinkage across the growth rings). Of course, as in this case, when shrinkage does occur it takes the path of least resistance – and manifests from a weak point on the outside of the tree.

There’s no real way to avoid this happening… except maybe avoid these types of trivets. Oiling it won’t help. In the end, one just has to live with it. It could be also repaired using a bowtie inlay.

P.S. There is a good guide to wood shrinkage and expansion here.

Making extension cords

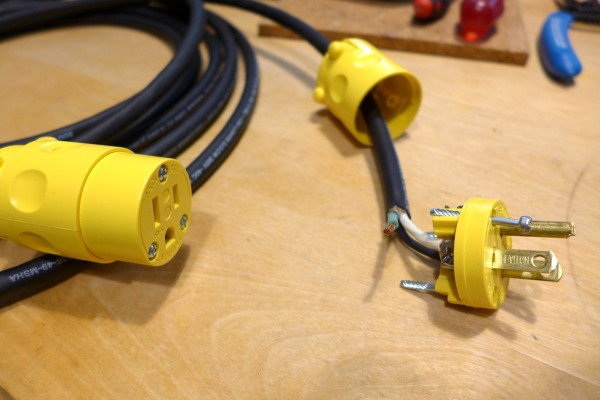

A couple of years ago I bought an expensive 12 gauge extension cord to power my tools in the backyard (my large “workshop”. It worked for a while, but now it suffers from the usual issue – an inability to being wound up in a proper fashion. I have never liked the cord… which got be to thinking if there is a better way? What about making extension cords? So, having bought some 14/3 waterproof wire for an LED lamp rewire, which turned out to be too big (go figure), I decided to turn this into a small extension cord.

The wire I’m using is made by Southwire (made in USA), and I bought it at HomeDepot by the metre ( 14/3 is C$2.49 a metre). It’s a rubber coated and water-resistant. It is somewhat overkill, as it is also flame and ozone resistant, but its core characteristics are high flexibility, and abrasion resistance. Plugs for the ends, C$9.98 and C$6.98.

Putting it together is super-easy, and a good task for someone who wants to try some simple electrical work (there are like a million tutorials online). It takes about 10 minutes to make. Just make sure you follow one of copious tables on the net to choose the right gauge wire for the length of extension cord you want to make.

End result? a water resistant, kink-free extension cord. I obviously wouldn’t leave it outside in the rain because the plugs are not waterproof… but then I wouldn’t leave anything electrical out in the rain (or snow). Next, I’m going to make a 25 foot, 12 gauge cord to replace the super-annoying one.

Vacations walking in forests

I wonder how much non-wwodworkers think about trees? Woodworkers likely spend too much time thinking about trees. When I took botany at university I thought it was boring, largely because it was all about Latin names and stuff like that. I mean some of them sound really cool… like nothofagus moorei, the Antarctic Beech, a magnificent tree. Who but a woodworker would think a holiday spent walking through forests was cool? And therapeutic. Walking through a forest helps via a practice the Japanese term Shinrin-Yoku, or forest bathing. Apparently walking around breathing in essential oils of wood is good for you.

So what forests are on my list?

- The forests of Haida Gwaii

- Hackfall Wood, North Yorkshire

- The forests of the Ardennes, near Bouillon

- Waipoua Forest, New Zealand

- Giant Forest, Sequoia National Park.

What about you?