Sunday was Tools of the Trades in Pickering (Ontario). I arrived just after opening (10am) to a hall full of tool sellers, and quite a few potential buyers. Lots of tools – maybe a result of the show being later than it normally is in the fall (or maybe I couldn’t see all the tools before because of the lousy lighting, which has been completely updated now). One of the oddest things about a show like this is tool availability. At the last show in April there were very few vises, and only a couple of mitre boxes. This time there were lots of both – especially vintage Record vises. But there are always plenty of planes (both metal and wood), chisels, drawknives, machinist tools, hammers, wrenches, some Japanese tools ($$$), books, catalogs (both reprint and vintage) – a bit of everything. It seems like there is always 1-2 items that are in abundance. Although, the more tools one collects, the more discerning one becomes at these shows. There is a *thin* line between tool collector and tool dealer. Sometimes, a tool may seem like a real bargain – but you always have to weigh up how much effort it will take to return it to working condition… and sometimes how many of them you already have. There is a point when collecting a particular tool (such as block planes) when it there is just less chance of coming across something new.

I spent the first hour looking. It’s hard not to get giddy with excitement when you first walk around – and the first thing that comes to mind – did I bring enough money! I don’t like making rash purchases, so the hour allows me to mull over what I have seen of interest, and what is on my list. First purchase was a razee coffin smoother made by “A. MONTY, ROXTON POND PQ.” ($18), most likely made of beech the plane, in almost perfect condition. I picked it up because it fits with my “collection” of razee planes, and it was made in Roxton Pond Quebec. This area is well known for wooden plane makers, with names such as S. Dalpe, GW. Willard, A. Monty, P. Nicol and even Stanley. Also bought a nice gouge chisel ($5).

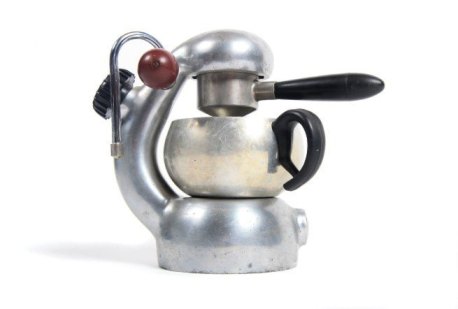

Next I bought a Millers Falls “Buck Rogers” style 104 (1/4″) drill ($12), and a 15″ Stanley Liberty Bell ($22) – a Model 127, type 4, 1905-1909.

Two of the things on my list: a protractor, in this case a Starrett No.19 ($12) and a drawknife ($22).

Two of the last three purchases were for the block-plane collection. Firstly a weird 8″ squirrel-tailed block plane ($15) with no maker on it – but I bought it mainly because the lever cap will fit a Stanley 203 I have with a broken cap. I’ll do something with the plane body if I can ever figure out who manufactured it. Secondly a Millers Falls No.7 skew block plane – the most I spent on a single item at $65. I pondered the No.7 for a while, but Millers Falls generally don’t sell as quickly – lesser known I guess, and everyone is after Stanley’s. Sargent planes are even rarer in this neck of the woods. The No.7 had nothing missing and was in great condition – hard to pass up, especially when the equivalent Stanley (No.140) always costs more.

The pièce de résistance – a Stanley 2246 mitre box with an Atkins-made saw for $40. Almost complete, one small broken leaver, and the length stop rod seems to be missing, but that can be replaced. I also bought a couple of books and a 1939 Stanley catalog. The books: “The Care and Use of Japanese Woodworking Tools” by Kip Mesirow and Ron Herman (1980), and “The Making of Tools”, by Alexander Weygers (1973) – $5 each.

All in all time well spent. I don’t like to haggle too much, but there are bargains to be had, and unique finds – even if sometimes you just buy them to preserve tool heritage. The next show is on Mar.30, 2014. Both Sauer and Steiner (metal/infill planes) and D.L. Barrett & Sons (wooden planes) were there – the planes that both of these makers are truly works of art – however over $2000 for a infill coffin smoother can be somewhat intimidating at a vintage tool show. I’d love to own one, but could likely never justify the cost, even though I know how much effort goes into producing one. Only, 4.5 months until the next show. Anyone knows of a source of vintage tools in Montreal, please drop me a line, I wouldn’t mind trying to find a couple more wooden planes made in Quebec.