Many people likely think the first true metal block plane was the Stanley No.9½, which appeared in 1872, but it wasn’t the first block plane. The first cast iron plane produced in North America was that of Hazard Knowles, in 1827. The first cast iron block planes were actually produced by Birdsill Holly in the 1850s. Born in 1820 in Auburn NY, at the age of 10 Birdsill Holly first apprenticed to a cabinetmaker, then a machinist. Although only having a 3rd grade education, Holly was a natural inventor. In 1848 together with Horace C. Silsby and Washburn Race Holly formed the company Silsby, Race & Holly Co. located in Seneca Falls NY. There he was the visionary behind the manufacture of hydraulic machinery and steam-powered fire engines.

The planes produced by Holly were very interesting, but honestly they seemed like a bit of a sideline because the company did not manufacture the planes for very long, only 1852-1859. In 1852 Holly received a patent (No.9094) for a “Hand-plane”, with improvements to metal hand planes, and began producing planes. The bench planes had a novel design with the base basically in the form of a flat iron. Instead of the blade being held in the plane by a wooden wedge, this new design used a metal sleeve with a locking screw. The underside of the sole in these bench planes sometimes incorporated relief holes to reduce friction, and other times offset corrugations, one of the first manufactures to incorporate this technology.

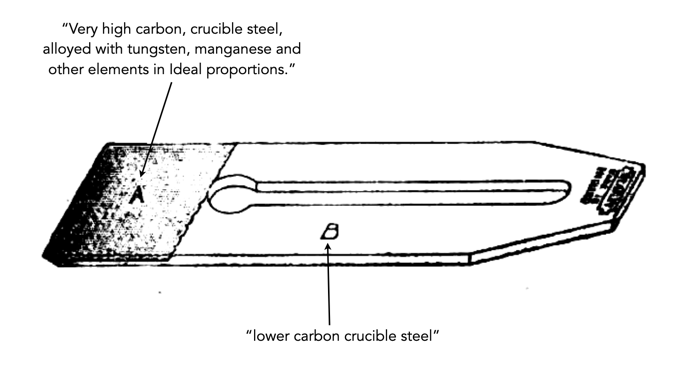

The bench planes were followed by what is arguably the first true metal block plane. The block plane had a tapered, boat-like shape, with a “shoebuckle” lever cap design. The lever cap essentially had cutouts in it, and pivots on the same type of metal rod found in simple block planes. A metal wedge or pin made or cast iron or brass would be slid in to hold the cutter down. Later versions had a brass screw cap to lock the lever cap against the cutter. There are very few of these block planes, and likely they were never commercially manufactured. However the plane design did contribute heavily to the development of the Stanley No.110 block plane, one of Stanley’s earliest designs. The 110 was essentially a complete rip-off of the Holly’s plane, but was completely legal as Holly has never patented the design. The other amazing thing about this block plane is that fact that it had 15° bed angle.

In 1859, around the time plane manufacturing ended, Holly created his own company, Holly Manufacturing Company in Lockport NY, where he worked on fire protection systems. In 1877 Holly formed Holly Steam Combination Company, working on a steam heating system. By the end of his life in 1894 Holly had amassed more than 150 patents. These block planes, if you are fortunate enough to find one, sell for upwards of US$1000 these days.