Modern planes come blades made of exotic types of steel, but what about vintage planes? For instance, what sort of steel did the Stanley’s use?

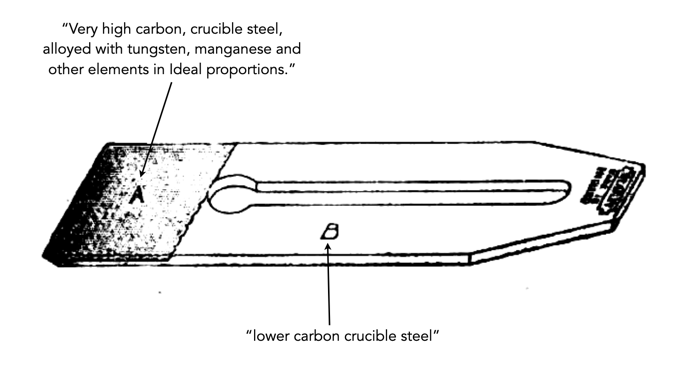

The short brochure “Read this before you use STANLEY PLANES”, describes the blades. It appears that for several generations the steel used In Stanley Plane Cutters was made for Stanley in one of the steel mills in Sheffield, England and was known as “Composite” Steel. It was comprised of a cutting edge of “very high carbon, crucible steel, alloyed with tungsten, manganese and other elements in ideal proportions”, and a softer backer made of lower carbon crucible steel. Both were welded together when cast, and made of the best quality Swedish pig iron.

It is hard to know exactly how long Stanley made these composite blades. There is no mention of composite steel in the 1906 Stanley catalog, just “English Steel”. Examining the various catalogs over the years, it is not until No.129 published in 1929 that there is any mention of composite steel. In Catalog No.34 (1915) it describes the use of “the finest quality English steel”, and by Catalog No.34 (1942) is had changed made in Sheffield, England from “the very best grade of Swedish iron”.

Sargent planes of the VBM type, short for Very Best Made, had blades made of the Very Best Tool Steel, whatever that seems to mean (it was a phrase used by many tool companies). Union planes were made out of “a superior grade of heavy steel”. A 1939 catalog from Swedish company E.A.Berg talks about “best quality Swedish steel”, compound-steel, and “Swedish Charcoal Steel”, but fails to discuss specifics. Maybe it was a proprietary blend, or perhaps they just felt that people wouldn’t be interested in the “chemistry” side of things.

Record made it well known that their blades were made using Tungsten steel. The concept is explained in Planecraft, first published in 1934. The tungsten combines with carbon to form tungsten carbide, a metal used in machine tools for high speed cutting of metals. Basically “a plane iron containing the correct amount of Tungsten is harder and more resistant to wear, and will take a keener cutting edge, and hold it for a longer period than would an ordinary steel.“. The tungsten also helps create a very small grain size, making a blade more resistant to shock.

Why did so much of the blade steel seem to come from Sweden? Swedish iron ore deposits contain small percentages of the element vanadium, which makes steel produced from it a natural alloy. The presence of vanadium allows production of a tough, fine-grained steel whose high tensile strength is not crippled by brittleness.

I think Stanley, Sheffield, used those composite blades right up to the late 70s. When I am restoring planes of that period the blades (irons) are put in rust remover and the higher carbon section always develops a distinctly darker colour to the lower carbon upper. It struck me as odd at first until I realised two different grades of steel were present.